Sections of the site

Editor's Choice:

- Business with China - where to start, how to find suppliers + TOP-15 goods from China and a list of trading platforms

- Where to invest 1000 dollars

- Three common misconceptions and six life tips

- How can maternity capital be used - what needs can be spent on maternity capital

- Caramel apples - a new idea for business

- Ready business plan for beginners

- Gypsum tiles for stone: 7 advantages of the material

- How to buy the best and interesting unusual goods from China for home, gifts and sale on Aliexpress in Russian?

- Business plan for opening a bath

- Where to spend maternity capital before the child is 3 years old

Advertising

| Gypsum tiles for stone: 7 advantages of the material |

|

Gypsum is a soft, ductile and lightweight building material, and with such qualities, it is naturally ensured popularity, as well as materials made from gypsum. Stone-like tiles are very popular, also such tiles have a wide range of shapes and textures, and they are made of gypsum. When choosing a plaster assortment of tiles, questions are asked, which manufacturer to choose, is it possible to make such a tile with your own hands, how to properly lay and grout? Gypsum tiles have a huge number of advantages, but there are also disadvantages. After familiarizing yourself with all the positive and negative sides, you have a choice whether to purchase such a stone made of gypsum or give preference to ordinary tiles.

7 advantages of gypsum tiles:

But, like any other material, gypsum also has its drawbacks, which you should also familiarize yourself with before purchasing. Disadvantages of decorative plaster tiles:

How plaster stone tiles are processedPlaster products are easily cut and machined. Such a tile is cut exclusively with a hacksaw, miter box, square, and the necessary holes are drilled with a drill. For gypsum tile renovations, the biggest challenge is the joining of the outer corners. In order for the docking to look perfect, you need to cut the gypsum tiles with a grinder at an angle of 45 degrees. After trimming, the slabs must be sanded.

You will also need to cut in those places where the installation of sockets and switches will be carried out and also at the junction of walls with floors. In the case of curved structures, it is necessary to carry out curved pruning and, if necessary, paint. In order to significantly reduce financial costs and the number of cut tiles, it is necessary to make markings on the surface where the cutting will take place, and the products that you have not yet unpacked must be sorted by shape, thickness and shade. Plaster decorative tiles: we carry out the correct installationFacing work with gypsum tiles is carried out on a prepared flat surface and on a dry base. To do this, we do the following:

In order for the hitch to be reliable, an acrylic primer is used. Gypsum tiles are decorative and therefore not used for cladding on wood surfaces and on damaged substrates. The manufacture of the adhesive is carried out strictly according to the instructions. Before preparing the glue, it is imperative to check the expiration date. Since the mixture quickly hardens, it does not need to be kneaded in large quantities.

There are the following types of adhesive mixture:

After all the necessary materials have been collected, you can proceed with the installation. Adhesive technology:

Molds for gypsum tiles: how to make a product yourselfIn order to start working on the manufacture of gypsum tiles, it is necessary to buy a mold for the manufacture of gypsum products in advance, which is made of silicone or polyurethane. Molds made from polyurethane are much more expensive than silicone molds, and the reason for this difference in price is that the polyurethane mold can be used not only for gypsum products, but also for other building materials. Self-made organization is possible if there is special equipment - silicone molds.

In the case of the presence of several elements of already made plates, the mold for manufacturing can be made with your own hands according to the sample of already made tiles. In order to make such a form, it is necessary to take a bath that must be airtight, then attach a sample to the bottom and fill the form with liquid polyurethane, it can be purchased at any point of sale of building materials. In order to prevent the poured form from sticking to the bottom of the bath and to the sample, before pouring in with polyurethane, it is necessary to lubricate these components with a fat-containing agent. After that, painting can be carried out. Coloring is done with special means. You can get acquainted with how the production of tiles and molds for it proceeds correctly in the training photos and videos. In addition, even a facing mosaic is created in this way. In some cases, people even start their own business. DIY silicone molds for plaster (video)Gypsum stone tiles are an excellent replacement for a real expensive stone, which not everyone can afford to buy. But gypsum is an ideal option, especially since products can be created independently based on our recommendations above. By doing this, you will significantly reduce your financial spending. Based on the above, we can say that gypsum tiles are the best option that you can buy and create yourself at a bargain price. |

| Read: |

|---|

Popular:

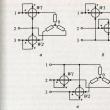

Power and energy measurement

|

New

- How birds differ from animals How birds differ from other vertebrates

- Scattering of folk wisdom Precious wisdom scattering of true caution

- How to make money on photo banks

- How I Sell Photos

- The scenario of the autumn holiday in the multi-age group "sorceress autumn"

- Congratulations on the day of the personnel worker Congratulate the personnel officer on the professional holiday

- Congratulations on the day of the personnel officer in verse

- A synopsis of a role-playing game on the topic: "All works are good, all professions are important" for children of the middle group, the outline of the lesson (middle group) on the topic Role-playing games by profession

- Educational project teaching Tatar as a foreign language

- Creative project for teaching the Tatar language "In the circus" - "Circus