Site sections

Editor's Choice:

- Business with China - where to start, how to find suppliers + TOP-15 goods from China and a list of trading platforms

- Where to invest 1000 dollars

- Three common misconceptions and six life tips

- How can maternity capital be used - what needs can be spent on maternity capital

- Caramel apples - a new idea for business

- Ready business plan for beginners

- Gypsum tiles for stone: 7 advantages of the material

- How to buy the best and interesting unusual goods from China for home, gifts and sale on Aliexpress in Russian?

- Business plan for opening a bath

- Where to spend maternity capital before the child is 3 years old

Advertising

| How perfume is made |

|

Every person knows about the existence of such a subtle matter as perfumery. Almost everyone, at the level of their sense of smell, has an idea of what exactly it is about - a pleasant aroma, enclosed in an elegant bottle, hidden in an elegant package, which is sold for a very large sum ... Not all, but very many at least once tried to "try on" yourself any of the many perfumery fragrances ... But almost no one knows about how perfume is made and what exactly it starts with ... The path of “dreams in a bottle”, so elusive and invisible, the history of any of the many thousands of existing perfume compositions originates in the perfumer's workshop. Before starting his work, the creator of the fragrances talks in detail with the customer or his representative and, meticulously asking about all the numerous wishes of his client, draws up a “brief” for the fragrance. Almost without exception, perfume and cosmetic brands, obsessed with the idea of making a perfume, turn to specialized laboratories such as, for example, the “Creassence” laboratory, located in the municipality of Louveciennes near Paris, to develop a formula for a new fragrance. Creassence was founded in 2000 by perfumer Sylvie Jourdet. The laboratory positions itself as the "House of French Perfumery", whose mission is to create and manufacture unique fragrances to order. Moreover, any client can order the development of perfumes in "Creassence" for any purpose: for himself, for a loved one, as a gift or for sale, for any holiday or event. In addition, Creassence specialists hold many seminars and conferences on perfumery and near-perfumery topics, in particular: “Scented Plants”, “The Art of Composing Aromas”, “Classification of Perfumery”, “Modern Trends in Perfumery Production” and others. Today, the arsenal of perfumers contains a fairly wide range of aromatics - more than 6,000 names of raw materials. The composition of one perfume alone can contain from 30 to 80 different components. Naturally, the price for each of them, depending on the complexity and complexity of obtaining, fluctuates in a very wide range.

For example, to get one kilogram of rose oil, you need to collect tons of petals, and to get iris oil, you must first tan its roots for two years. Vegetable raw materials are alcoholic infusions, solutions and oils obtained from the fragrant parts of plants: leaves, seeds, fruits, roots, as well as some mosses and lichens. Plant resins and balms are also used. Raw materials of animal origin are most often understood as ambergris, beaver stream, musk and civet. By themselves, they exude scents that cannot be called pleasant, but thanks to them, perfumers give their creations more sensuality, attractiveness and voluptuousness ... But back to how spirits do. It takes an experienced professional perfumer from two weeks to three months of hard work to develop a fragrance, depending on the wishes of the customer. In fact, it is not so important which fragrance is classified and for whom exactly it is developed. Whether it's Nina for women or Nina Ricci's L "air du Temps", Paco Rabanne Pour Homme for men or Paco Rabanne Ultraviolet Man for Paco Rabanne, the manufacturing process is always the same. : the perfumer, guided by the information from the "brief" on the aroma, his own flair and intuition, composes a new perfume composition from various essential oils ... Drop by drop ...

And now, about three months of work on the fragrance is over. The time comes to select the most successful options. There is also a certain testing system: out of about 30 samples, about three or four perfumes should remain, maximum - five, which are destined to be presented to the client. The next photo captures a typical working moment in the work of perfumers in the Creassence laboratory - testing, evaluating and discussing perfume samples created in the walls of the laboratory at the request of one of the clients.

Left - Sylvie Jourdet, perfumer, professor and honorary chairman of the French Society of Perfumers (SFP), founder of Creassence. Sylvia received her perfume education at the famous French Institute of Perfumers ISIPCA (Institut Superieur International du Parfum, de la Cosmetique et de l "Aromatique alimentaire" - "International Institute of Perfumery, Cosmetics and Food Fragrances"). Right - Katel Plisson (Katell Plisson) is a perfumer, lecturer at the French Institute of Perfumers "ISIPCA", was educated in chemistry and fine analysis at the University "Le Havre". If the client is satisfied with the perfumer's work, he orders the production of a concentrate of the invented perfume in the laboratory. In perfumery slang, such a concentrate is called "juice" ("jus"). Those aromas that do not suit the client will remain in the laboratory's archives, "under the cloth of the perfumer's table." It happens that in the future, such fragrances still begin to be released. For the sake of fairness, it should be noted that customers (including large brands) very rarely buy out recipes for created aromas from the laboratory. Therefore, it is the perfume laboratories that are the owners of such recipes. In the next photo, Katel Plisson, the perfumer of Creassence, is making the concentrate. Just imagine how fragrant the atmosphere reigns within the walls of the laboratory at this moment! However, professionals know how to abstract from the cacophony of aromas and even focus on one of them in such a way that others are simply "inaudible" while working.

What is the cost of the future perfume concentrate and how much will it cost a potential customer to make the "juice"? Naturally, the lion's share of the costs is due to the cost of the ingredients included in the perfume. And, by the way, many of them are bought in the French Grasse - the historical capital of perfume, the Mecca of world perfumery. How much does it cost to make a perfumeHere are just a few facts for example: ● 1 kilogram of musk deer musk costs about 60,000 euros. Such components are used only in the production of only the most exclusive perfumery. But, of course, not everything is so expensive: Perfume factoryThe Paco Rabanne perfume factory was built in 1976. Despite the fact that almost 40 years have passed since its construction, this production with an area of more than 14,000 square meters is equipped with the most modern equipment, which employs about two hundred employees of various specialties.

The Paco Rabanne factory is not the only one in the region. The Association of Manufacturers of Perfumery and Cosmetics "Cosmetic Valley" has more than 130 large and small factories for the production of perfumes and cosmetics. Only one Paco Rabanne factory produces perfumes for such prestigious brands as Calvin Klein, Christian Dior, Guerlain, Hermes, Lolita Lempicka, Nina Ricci, of course Paco Rabanne and many others. All in all, the perfumery factories of Cosmetic Valley employ 16,000 people, annually producing a variety of aromatic products worth more than 2.5 billion euros. Nina Ricci Nina AchievementsAt the time the photographer took these pictures, the factory was in full swing producing a batch of Nina perfumes by the house of Nina Ritchie and Paco Rabanne pour homme by Paco Rabanne. To appreciate the production capacity of this factory, just try to imagine: ● The Nina fragrance by Nina Richie has been released since 2005. Let's take a look at how the Nina perfume is made at the Paco Rabanne factory. In the course of the production cycle, the future Nina concentrate from Nina Ricci will go through numerous high-tech stages of dissolving the perfume concentrate in rectified alcohol, allowing the resulting solution to stand, freezing, filtering, fine purification, packing and finally packing. And all this will take place under the constant supervision of the highly qualified personnel of the factory. Factory laboratory

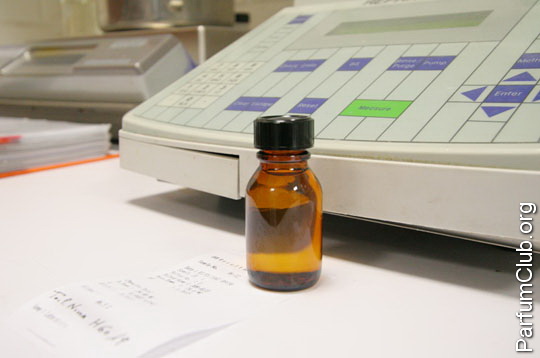

The enterprise has its own chemical laboratory. It should be said that there is a very important document - "Regulations on perfumery and cosmetic products", which strictly regulates everything related to the production, quality and safety of the respective products. Judging objectively, the six full-time laboratory assistants have a lot of work and they do not have to be bored. Everything that is shipped from the finished product shops of numerous perfumery and cosmetic enterprises, all products that go to stores and boutiques, must comply with the above provision. In this regard, perfumes are made under the constant supervision of the factory laboratory. Tests are carried out by Paco Rabanne specialists at all stages of production. The first tests begin immediately upon arrival at the feedstock plant. In the photo below - a sample of a mixture of perfume concentrate and rectified alcohol arrived at the laboratory for a control test. And further, the entire technologically complex process of making perfumery up to the completion of the packaging of the final product also takes place under constant control.

Most likely, you do not know or have not thought about the fact that despite the considerable cost of perfume, in fact, only 20-25 percent, maximum 30 percent of their price is the cost of the perfume composition itself. (I mean the final product of production - those very intricate bottles in beautiful cardboard boxes that are sold in perfumery boutiques). It is in the chemical laboratory of the enterprise that the final "fine-tuning" of the concentrate of future perfumes takes place. The concept of "commercial secrets" is well known to perfumers and is followed by them no worse than the bankers of Switzerland. For this reason, the recipe for the perfume is not disclosed even among the employees of the Paco Rabanne factory. None of the many engineers, laboratory assistants and technologists knows him completely, not to mention the ordinary workers of the enterprise. For many of them, there are only numbers in various tables and forms. No more than three people from the industrial group "Puig" know thoroughly the whole process from start to finish and, accordingly, the secret formula of the perfume.

Another equally important and responsible task is faced by the laboratory staff. They constantly monitor the stability of the finished perfume product, including - they are engaged in the preservation of color, other physical properties and aromatic qualities of perfume over time. Simply put, factory-released perfumery products are stored and periodically tested for 3 years after release for their physical condition and olfactory properties. Organization of production

The pace of work at the Paco Rabanne factory is quite intense and these requirements are dictated by modern business processes. Every day, the delivery service delivers dozens of concentrated perfume aromas and a colossal amount of rectified alcohol to the warehouse of the enterprise, the mixture of which will soon turn into an incredibly beautiful perfume or eau de parfum. The organization of the work of this entire grandiose mechanism is planned in accordance with numerous applications coming from large wholesale and small trading companies. One of the most important stages in the production of perfume is the process of mixing a perfume concentrate with rectified alcohol. For these purposes, they use huge containers of various capacities made of high-quality inert stainless steel (in the photo below - on the right).

In the photo below, on the left, you can see a flipchart - a special board on which the plant's engineers make notes on the progress of production processes: on which of the numerous production lines and what exactly is happening at a given time. The technologists of the Paco Rabanne perfumery factory scrupulously make notes on the course of all production processes. This organization of work allows the Paco Rabanne factory not to be out of schedule and fulfill the finished product delivery plan on time, without letting down its business partners from France and other countries.

The production of high-quality perfumery today is a real team work, requiring impeccably accurate and timely execution of all necessary procedures and technological processes by all team members. Only the slightest mistake or inaccuracy at any stage of production can entail colossal losses for the entire enterprise. Preparation of perfume compositionIn 2005, work was completed on the automation of technological processes of the enterprise. As a result of the technical re-equipment of the factory equipment, the new production lines are now controlled by computers that completely control all the processes of making perfumery. But still, robots, supercomputers and all kinds of manipulators will never be able to completely replace humans in production. In this photo, the technologist controls the process of adding rectified alcohol and dye to the future perfume composition.

Ahead - "maceration". For 15 - 20 days future perfumes will “mature” in a huge tank made of inert stainless steel, called “cuves” in the language of perfumers. The mixture in the tank will be stirred daily for one hour every day. This technological process is fully automated: the computer will do all the work with its inherent accuracy, the control over the computer is carried out by a person. These "cuvées" do not yet contain perfume, but only a mixture of perfume concentrate, dye and rectified alcohol. In the stainless steel tank, which is the very first in the photo, the famous women's eau de parfum "Ultraviolet" from "Paco Rabanne" is currently "ripening" ...

The giant industrial tanks hold about a thousand liters of a mixture of concentrate with rectified alcohol. The proportion in which they will be mixed in each case is precisely determined, is always very precisely observed and is usually not disclosed by perfumery engineers. Nevertheless, if we talk about perfumes, then from such a thousand-liter vessel at the end of the production process, about 6,000 liters of elite perfumes will be obtained. In this huge hall, with the help of powerful industrial air conditioners, the temperature is constantly maintained at 15 degrees Celsius. Here not only the perfumes of numerous brands belonging to the Puig concern “mature” before entering the bottles, but also the perfumery of the houses of Christian Dior and Guerlain.

In huge stainless steel tanks for a long period of time - from 15 to 20 days - "maceration" of the mixture of perfume concentrate and rectified alcohol takes place. The production capacity of the Paco Rabanne factory at this technological stage cannot fail to impress: ● The price of one stainless steel tank is from 20,000 euros each. After the "maturation" process, future perfumes go to the factory production lines for further processing. Work at the factory does not stop even at night, and since several production lines are working at once, on which the production of various perfumes is being prepared, it is very important to keep strict and careful records. This is another component for obtaining excellent perfumes of excellent quality ... Like circus jugglers, three high-class specialists are responsible for launching fragrances into production, skillfully manipulating thirty production lines at the same time. It should be noted that these are only lines for the production of branded perfume. In addition, the factory regularly carries out many small orders for the production of seasonal fragrances and limited edition perfumes, produced in limited edition ... Filtering perfumeThe process of filtering a perfume composition during the production of a “dream in a bottle” is indispensable. After the future perfumes leave the "cuvée", they undergo thorough filtration, the task of which is to remove the smallest impurities, which could later somehow manifest themselves in the finished product and spoil its impeccable appearance. In the photo below, the popular men's fragrance Pour Homme from the Paco Rabanne house is being filtered. The filtration system is quite complex, and the process itself is carried out shortly before the perfume composition is fed to the filling line. Future spirits will have to pass under pressure through 25 finest filters, preliminary mechanical and fine cleaning, which will not let anything superfluous into a high-quality product. And this is just the beginning of cleaning ...

Freezing spiritsThe next process is used after the stage of pre-filtration of the liquid for even more effective cleaning, it is called "freezing" (perfumers say "glacage") and is used to remove wax-like substances from the perfume composition, which is ultimately done to increase the stability of the final product.

The mixture of rectified alcohol and perfume concentrate is now cooled to 0 degrees Celsius. At this temperature, vegetable waxes, poorly soluble in alcohol, crystallize, precipitate and are subsequently removed from the finished product. Freezing makes future perfumes as transparent as possible and avoids the appearance of any clouding of the perfume composition during its long-term storage. The freezing process takes place in special apparatuses - displays or crystallizers. The cycle can be either continuous or periodic, and it is possible to send a perfume composition for re-filtration. In the photo above, with frost-covered pipes, it is just one of such powerful and productive units for freezing. Vials and packagingIt is not enough to make a high-quality product - you need to put it into a beautiful shape: pour it into bottles and pack it. For this, the factory makes a warehouse stock of very diverse components - bottles, spray guns, boxes, decorative elements and plastic wrap, which, by the way, are individual in design for each perfume product.

Manufacturing cannot afford downtime due to a lack of consumables and thus let down customers. Especially when you consider the fact that for the release of many limited editions, packaging materials are ordered in separate batches or even one-time. Therefore, warehouse stocks are created taking into account the possible appearance of increased demand for a particular brand of perfume and work without frequent additional deliveries of components in the period from three months to six months. This is where the perfume ends up - on these production lines, where the time-consuming packaging process takes place. The Paco Rabanne factory has six automatic production lines and four semi-automatic ones. The packaging of finished perfumery products, working in 3 shifts, 8 hours each, employs sixty people on a permanent basis.

The bottles for the Paco Rabanne finished perfume filling lines come from the Normandy glass factories located near the town of Le Treport. Major suppliers of glass perfume bottles are the most prominent in the industry. First of all, these are the enterprises "Pochet", "Bormioli" and "Saint Gobain Desjonqueres".

Filling and packaging linesThe production capacity of only one conveyor on which finished perfumery products are bottled and packed is from 1000 to 1600 bottles per hour, and this indicator depends on the complexity of the design of the bottle itself. Accordingly, 24,000 to 38,400 bottles leave the automatic line per day. One more nuance should be noted. Intensive work is in full swing on the conveyors of the enterprise and so that fragile bottles do not break, they are moved along the conveyor in special stands, which, in turn, are also made specifically for the design of the bottle. In this photo - bottles of "Nina" from "Nina Ritchie" begin their movement along the factory conveyor.

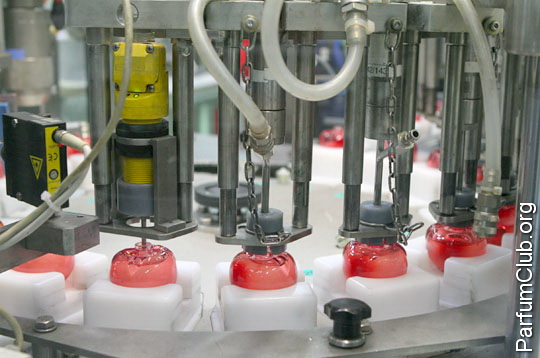

The lines that dispense ready-made perfumes operate non-stop 24 hours a day. In total, the Paco Rabanne factory has four semi-automatic and six automatic lines for filling and packaging perfumery products. This photo (left) shows how six bottles of "Nina" are filled simultaneously through special nozzles.

A special sensor is mounted in the seventh nozzle of the finished product filling line, which checks the filling level of the bottle, because the “Nina” fragrance from “Nina Ricci” is bottled in various bottles with a volume of 30, 50 and 80 milliliters. A modern perfume bottle is practically unthinkable without a spray bottle. Its use makes the use of perfume more comfortable for the consumer and allows the scent to be consumed in a metered manner and more economically. Every day, the production lines of the enterprise install thousands of such as shown in the photo, sprayers.

The largest supplier of atomizers for the production lines of the Paco Rabanne factory is Valois, which today is a recognized leader in the design and manufacture of high quality atomizers and other spray systems for the perfumery, cosmetic and medical industries. The process of final installation of sprays is fully automated and takes place on a special pressing device. The operation is performed by manipulators without human intervention. Previously, thin plastic tubes through which the sprays will subsequently deliver the aromatic liquid are cut to the desired length. The need for trimming arises due to the fact that initially all sprays are made with tubes of standard length, and the perfume can be poured into bottles of various sizes and heights.

The time that each bottle spends on the device for pressing the atomizer is less than one and a half seconds. With just a few precise movements, the elegant container moves to the next section of the packaging process. The famous Paco Rabanne brand cannot make any claims to the quality of its luxury products. In this regard, the requirements for quality control of finished products are very stringent. Since thousands of sprays are installed on production lines by automatic machines, one of the many validation tests is the quality control of the spray gun mechanism ...

At the site for control of finished products, manipulators cannot yet replace human labor. In the photo above, you can see that at the Paco Rabanne factory every bottle of perfume is hand-checked. After the next check, it's time to pack the vials. Vials are placed in cardboard boxes on new generation packaging lines, which are characterized by high speed and productivity. The robotic device grips the bottle and places it in the box with precise movement. Another manipulator with a soft felt pad sends the bottle to the very bottom of the cardboard box.

The bottles of "Nina" have a fairly simple design. Some other flavors may have more complex shapes and require more manipulation of their packaging, which will affect the pace of packaging. An automated line for packing perfumes into cardboard boxes is usually programmed to run continuously for 12 hours. Naturally, the automated packaging process takes place under constant human control. A robotic packaging line does more than just put bottles into boxes. Film packaging provides a beautiful appearance of the packaged perfume. Therefore, at the end of the packaging process, the production line closes the cardboard box, wraps it with film and thermally fixes it. It should be said that special requirements are also imposed on film packaging. Even at the beginning of packaging, the film should provide excellent physical properties, be resistant to stretching and puncture resistance, and should fit snugly around the perfume box in order for its appearance to be attractive and aesthetic.

It takes just one minute - and 40 packaged bottles come off the automatic line. Foil-wrapped boxes run along special rollers to the end of the conveyor. It will take approximately another minute to manually move 40 vials into a large shipping box.

Perfume boxes are collected on transport pallets. Almost everything is ready for sending a batch of perfumes to the customer. An employee of the Paco Rabanne factory makes the final marks on the boxes before the pallets are wrapped with plastic cord and wrapped in plastic wrap. There is another stage ahead, as a result of which the next batch of perfumery will be prepared for loading into trucks and will be sent to authorized brand sellers not only in France, but also around the world. The finished products are not stored directly at the Paco Rabanne factory. Large cardboard boxes, inside of which are small boxes with perfumery, collected in 24 pieces on special cargo pallets, go to an automated product transportation system. Pallets slide on conveyor rollers further, where two robotic units are engaged in product distribution.

The transportation system of the enterprise, operating at full capacity, can simultaneously serve up to ten production lines. State-of-the-art control technology gently sets in motion and stops loads, thanks to which even such unstable and fragile cargo as perfume is safely and reliably transported and sent to the warehouse. The starting price for transportation systems of this class ranges from 200,000 euros and more. In order to avoid theft of finished products, Paco Rabanne follows a very simple security policy: never store finished products on their premises. Immediately "from the stocks" of the factory transportation system, the products are sent to the cargo terminal located in the suburbs of Paris. |

| Read: |

|---|

Popular:

Power and energy measurement

|

New

- Tired MPs want to give Russians a two-hour lunch break. Concepts and categories

- Massage covers Relaxation cape

- Relaxation cover Ergopower ERSC7H Contraindications and benefits of massage cover

- How to pay for utilities directly to the resource supplying organization When we pay directly to utility providers

- Recommendations for finding a job abroad for Russians, Ukrainians, Belarusians

- Forgot the code word belagroprombank How to set up a mobile key belagroprombank

- The habits of rich people: behavior, thinking and interesting facts What makes a person rich ask

- Belagroprombank personal account Fransabank internet banking login

- How to make money on agricultural tourism in Russia How to open an agricultural estate in Belarus

- How much is the labor of a kindergarten teacher in our country and in other countries?