Site sections

Editor's Choice:

- Business with China - where to start, how to find suppliers + TOP-15 goods from China and a list of trading platforms

- Where to invest 1000 dollars

- Three common misconceptions and six life tips

- How can maternity capital be used - what needs can be spent on maternity capital

- Caramel apples - a new idea for business

- Ready business plan for beginners

- Gypsum tiles for stone: 7 advantages of the material

- How to buy the best and interesting unusual goods from China for home, gifts and sale on Aliexpress in Russian?

- Business plan for opening a bath

- Where to spend maternity capital before the child is 3 years old

Advertising

| How to start the production of insoles and shoes on a 3D printer from scratch, where to start and how much you can earn. We produce footwear for the Russian Federation, we print for Europe |

|

Do you want to open a business that will bring tangible profits? Making and selling footwear in Russia or in European countries is a great way to start a new business or expand an existing one.

Many people lack affordable and suitable footwear. It is almost impossible to buy high-quality orthopedic shoes that fit perfectly on the foot. Manufacturing high-quality shoes, as well as insoles for them, its cost will be significantly cheaper than that of counterparts from the EU countries. In Russia, Moscow and St. Petersburg have the greatest prospects for doing business. In these cities, you can open a profitable business that will continue the traditions of the European brand. Another direction is the manufacture of shoes and insoles using 3D printers. These shoes do not chafe the feet, promote air flow and can be made in minutes. Manufacturing processThe basis for running any business is setting up a production line. The tasks of a novice entrepreneur include renting or buying suitable equipment, tools, as well as finding people specializing in cutting and orthopedic technologists for the production of orthopedic insoles and shoes. It will be much easier to promote itself if you already have a ready-made shoe business that you want to expand by adding a new direction. Instant manufacturing of orthopedic insolesAccording to statistics, only in Russia more than a third of the total population experience problems with the musculoskeletal system. This forces people to experience constant inconvenience when wearing regular shoes, some are looking for an alternative as orthopedic insoles. Accordingly, the demand for these products is quite high, and there are not enough companies capable of providing affordable services to everyone.

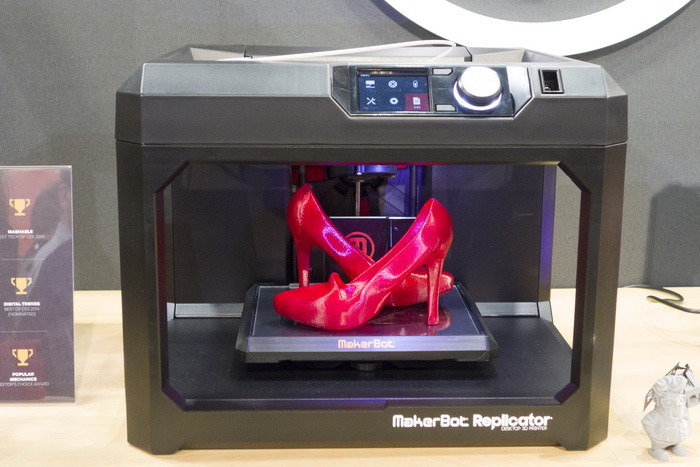

For the manufacture of orthopedic insoles, a technique with the use of orthopedic foam was previously used. It is comparatively time consuming and, just as important, it takes a lot of time to get the desired result. Therefore, it is necessary to work with more modern methods, using thermoplastic plastic, which is considered promising by specialists in this field. The use of this technology allows for individual modeling of the shape of the client's foot, including for shoes with high heels, and making changes in the correction of the shape during its operation (which is important for children with severe deformity of the foot). The indisputable advantage of the production of flat orthoses-semi-finished products from thermoplastic plastic is the time to manufacture one pair, which takes on average 30 minutes. The client comes and immediately buys the insoles he needs, as if the groceries are in a store. When exposed to high temperatures, the thermoplastic insole becomes softer, which allows you to create an insole that fits perfectly under your foot. Its production takes place on a flat surface or on a suitable last (for high-heeled shoes). For continuous production, special equipment is used - plankstop with a measure. The main advantage of 3D printing shoes is the ability to produce at home. All you need to do is buy a high-quality printer, purchase raw materials, consumables and your mini-business is ready to open.

The production of shoes on a 3D printer is available to every mid-level PC user. You are required to:

After a little time, you will receive new ergonomic sneakers or boots. No gathering or stitching, gluing instep supports and stuffing heels. The entire sneaker on the printer is made in one piece in one cycle, which makes it durable and protected from moisture. Ample opportunities to adjust the value of the original model allow you to create shoes that will fit perfectly on the foot. Individual sewing of leather shoes. Complement or core business

The production process of tailoring exclusive leather shoes seems to be the most difficult and is divided into several stages. The first stage begins with the cutting shop. Here, individual parts of the shoe are produced from pre-prepared leather. For this, a stencil and special punching presses are used. The insoles for the future boot are also cut out. First, the insole material is pressed, forming the desired shape, then the edges are sanded and it goes through another pressing stage, glued with a special glue. The next step is the markup. In this case, seams and joints are drawn. Next, the finished workpieces are sent to the kiln for firing, which helps to soften the insole. This is necessary for further work. The next step is the sewing workshop. It must be equipped with special installations that sew together the parts prepared in the previous stages. Then thermoplastic inserts are glued in and processed with a special machine before gluing the sole. The sole itself is made of polyurethane or rubber, after gluing to the boot, its excess parts are cut off with a knife. At the final stage, the finished boot is polished with wax and laced up. Where and to whom to sellThe shoe business allows you to use a variety of marketing channels. For the sale of orthopedic insoles, you can conclude contracts with medical institutions. This business is closely intertwined with the field of medicine and brings its owner a high income. It is better if you open your own salon in which qualified specialists will work. People with problems with the musculoskeletal system are more likely to trust and go to such a salon than to order insoles on the Internet or in a regular shoe store. On the other hand, the opening of several outlets for the manufacture of orthopedic shoes in a small town has its advantages. Relatively low production costs and availability to each client open up broad prospects for a novice businessman. If you open a mini-business for 3D printing shoes on a printer, then finding clients on the Internet will not be difficult. or a group on a social network describing what and how you are doing. As a rule, sneakers are printed on such printers, the shoes that are in the greatest demand. Opening an online store of stylish and practical footwear with delivery around the city looks like an interesting prospect. In addition, you can start a business by your own efforts, combining the work of a technologist, manager and courier.

Sewing exclusive leather footwear requires substantial upfront investment. When starting such a business, be prepared to work with individual orders. But there is no need to write off the idea of cooperation with retail chains, since this will save you from many problems associated with organizing a large shoe business. The main thing is to ensure the proper quality and comfort. You can sell not only on the territory of the Russian Federation, but also to European countries via the Internet. Also, a good option would be to open a European brand within the framework of a ready-made shoe business. The availability of footwear in different price segments and for different classes will ensure greater market capture and stable profits, regardless of the economic situation in the country. A step-by-step plan - where to start a business and how to start the production of orthopedic insoles and shoes on a 3D printer from scratchThe stages of organizing a business will depend on its type. 3D shoe printing provides an opportunity to work from home. At the same time, you will not need to rent additional space and hire a staff. The purchase of raw materials and delivery can be done by yourself, but with regard to permits for production and sale, an important role will be played by what parties and to whom you will sell. Everything you need for work: a computer, suitable software, 3D models of shoes and a printer. It is imperative to create a website on the Internet, which in the future may develop into an online store. It will be more difficult to organize a workshop for sewing leather footwear. If you do not have a ready-made shoe business, within which you can open your own European brand, then you will have to draw up a business plan, including the following points:

Advice For the production of orthopedic insoles, it will be necessary to additionally obtain a license to practice. Many salons that provide such services to clients employ orthopedists, surgeons and orthopedic technologists on their staff. How much money does it take to open we produce insoles and shoes on a 3D printerIt will take about $ 8 thousand to 3D print shoes at home. The main costs will go to the purchase of the printer. A good Lewihe Sneaker model costs around $ 3,000. He knows how to work with all kinds of operating systems, uses printing fiber - PLA filament, Filaflex with a diameter of 1.75 mm and has a print speed of 150 mm per second. Over time, you can purchase an additional printer. The Lewihe ProXL model costs twice as much (about 6 thousand dollars), but it has better technical characteristics and allows you to print a sneaker in one session.

The opening of a small orthopedic office, according to the most conservative estimates, will cost about half a million rubles. List of costs:

The production of leather footwear requires an initial investment of several million rubles. It is necessary to rent production halls, an office to work with clients. The purchase of equipment can cost 1-2 million rubles. Raw materials must be purchased in square meters:

It is not profitable to open such a business in a small town from scratch. To make the business profitable, it can be organized in large cities such as Moscow and St. Petersburg, as well as work on order, including with clients from European countries. How much can you earn by starting a shoe production on a 3D printer?Shoes, printed on a 3D printer, can be sold at a price of 1,500 rubles. Typically, such a business is focused on making a profit from a large number of sales. For an additional fee, you can organize the printing of shoes in the presence of the client on an individual order. If you have a good website, you can earn 120-150 thousand rubles a month clean. Information The cost of making an orthopedic insole together with measurement will cost 4-5 thousand rubles. Additional income will be brought by services for the correction of insoles, as well as consultation with a specialist in this area - an orthopedic surgeon. With the development of the client base, you can count on an income of 300-400 thousand rubles / month net. High-quality leather shoes can be sold for 10 thousand rubles or more. If you cooperate with retail chains, half of the profits will have to be paid for the sale of your product. This option is preferable only in case of high demand for products. For starters, you can try an online store with an individual approach to each client. Opening a line of high-quality European footwear with its own footwear business will provide a stable income in the amount of 300 thousand rubles per month. What documents are needed to open a shoe production on a 3D printer - registration and registration

To sell manufactured footwear and insoles, you need to register your business in the organizational and legal field and obtain the appropriate permits. Let's dwell on each of the points in more detail. What you need to produce insoles and shoes on a 3D printerThe best form for registering a business is an individual entrepreneur. In this case, it is necessary to register with the tax and pension fund, provide documents:

Information To cooperate with retail chains, you will need to register an LLC. The list of documents is supplemented by the company's charter. What OKVED must be indicated when registering a businessTo register with the tax office, you must specify the OKVED activity codes. There is a special code 19.30 for the production of footwear. Also suitable for starting such a business are:

Do we need permission to produce insoles and shoes on a 3D printer?To sell adult footwear, you must declare it. Only children's footwear undergoes mandatory certification, adult footwear is at the discretion of the manufacturer. Also, the manufactured goods must meet the relevant GOSTs and be under the control of the Sanitary and Epidemiological Service. Industrial and administrative buildings are checked by the fire control service. For the production of orthopedic insoles, you must obtain a license to practice. |

| Read: |

|---|

Popular:

Power and energy measurement

|

New

- Tired MPs want to give Russians a two-hour lunch break. Concepts and categories

- Massage covers Relaxation cape

- Relaxation cover Ergopower ERSC7H Contraindications and benefits of massage cover

- How to pay for utilities directly to the resource supplying organization When we pay directly to utility providers

- Recommendations for finding a job abroad for Russians, Ukrainians, Belarusians

- Forgot the code word belagroprombank How to set up a mobile key belagroprombank

- The habits of rich people: behavior, thinking and interesting facts What makes a person rich ask

- Belagroprombank personal account Fransabank internet banking login

- How to make money on agricultural tourism in Russia How to open an agricultural estate in Belarus

- How much is the labor of a kindergarten teacher in our country and in other countries?