Site sections

Editor's Choice:

- Business with China - where to start, how to find suppliers + TOP-15 goods from China and a list of trading platforms

- Where to invest 1000 dollars

- Three common misconceptions and six life tips

- How can maternity capital be used - what needs can be spent on maternity capital

- Caramel apples - a new idea for business

- Ready business plan for beginners

- Gypsum tiles for stone: 7 advantages of the material

- How to buy the best and interesting unusual goods from China for home, gifts and sale on Aliexpress in Russian?

- Business plan for opening a bath

- Where to spend maternity capital before the child is 3 years old

Advertising

| Raise3D: 3D printing to replace traditional shoe manufacturing |

|

Gradually, 3D printing penetrates into all areas of our life. In addition to the usual directions, such as prototyping, creating architectural models, parts, master models, household items, etc., 3D printers are used for other purposes. The production of footwear using additive technologies is not a new direction, but at the moment it is not widespread. There are companies that use 3D printers as an additional element to the main production - the creation of accessories, jewelry, and shoe design elements. Some of them make shoes on a 3D printer on a turnkey basis from insole to sole =) Raise3D's customers include two companies that use 3D printers to make specialized sneakers and smart insoles. Let's tell their stories. Creation of specialized sports shoes on Raise3D 3D printers At 25, Oliver Brossmann is already an entrepreneur and designer of unique sports shoes. As a child, he, like many boys, dreamed of becoming a professional football player. But after undergoing knee surgery in high school, I had to say goodbye to the dream. During his recovery period, Brossmann began exploring approaches to running and exercise with minimal stress on the joints and knees. At Brossmann College, in addition to basic subjects, he attended a couple of computer science and prototyping classes. With the goal of bringing his business idea to life and putting this knowledge into practice, Oliver left college and started working on his own startup, Prevolve. This project was developed from scratch with a small investment from a private investor. Oliver's startup at the moment is Oliver himself, a couple of part-time employees and his sister, who helps with work moments.

After 3 years, Brossmann officially launched his company's first product, BioRunners. The shoe was created on the BioFusion platform, developed by Oliver for 3D printing special sports shoes. Combined with a professional foot scanner that produces accurate scans, the product just got better and better with every iteration. Prevolve shoes are printed with TPU, a material that is durable and abrasion resistant. In the Prevolve online store, customers can choose the right color, shock absorber and tread thickness - for trail or street running. “Each pair of shoes is designed for a specific foot and, accordingly, the shape of each is unique. I am still thinking about upgrading the design to make the shoe more attractive and performance-enhancing, ”says Oliver. Prevolve shoes take between 20 and 30 hours to 3D print, depending on size. Oliver uses Raise3D printers, which are optimally sized for sneakers. Buyers of Prevolve shoes are athletes, professionals and amateurs, as well as people with special feet (different foot sizes, flat feet, etc.). 3D printed shoes are the cheapest and fastest to manufacture compared to orthopedic shoes. , custom-made in the traditional way. 3D printing of smart insoles on Raise3D N2 Dr. Roy Cheng of Gait & Motion Analysis Lab is the creator of smart smart insoles that are 3D printed. Roy himself is fond of jogging and wanted to buy smart insoles for himself, but the expensive market value made him think about implementing this project himself. Roy specializes in running biomechanics, the effectiveness of prophylactic devices for athletes, training in rehabilitation and injury prevention, and has received major research grants for his developments.

Both creating a custom insole and smart insoles using traditional methods is a complex and expensive process, and the target audience is very narrow. Disadvantages of the traditional method that Roy Cheng and his team used in the beginning:

The equipment list includes: computer, scanner, printer instead of thermoforming and grinding machine. Smart insoles are made up of electronic sensors and a thermoplastic base. The manufacturing process can be divided into three main stages:

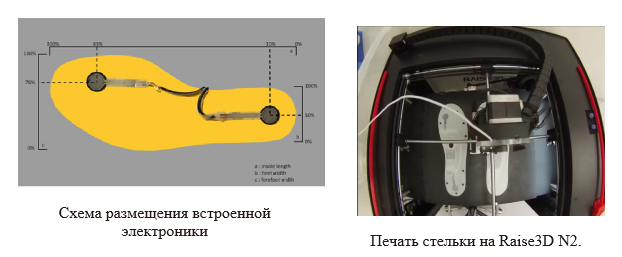

Using a rendered model and 3D printing, Roy maximized the protection of the electronics located on the insole. This was done by correctly placing all the components on the insole and by controlling the firmness of the insole by choosing the right filament and the percentage of filling the model when printing. All electronic components are placed between layers.

By using 3D printing, Roy's company was able to eliminate most of the insole manufacturing processes. Raise3D N2 can build a finished product inside and out with an individual insole shape and a specific arrangement of elements, and will automatically leave space for the circuit. After installing the circuits, the printer completely covers the electronics, printing the top additional layers.

By automating this process, labor costs, equipment costs and lead times are reduced. Tsvetnoy Mir team |

| Read: |

|---|

Popular:

Power and energy measurement

|

New

- Tired MPs want to give Russians a two-hour lunch break. Concepts and categories

- Massage covers Relaxation cape

- Relaxation cover Ergopower ERSC7H Contraindications and benefits of massage cover

- How to pay for utilities directly to the resource supplying organization When we pay directly to utility providers

- Recommendations for finding a job abroad for Russians, Ukrainians, Belarusians

- Forgot the code word belagroprombank How to set up a mobile key belagroprombank

- The habits of rich people: behavior, thinking and interesting facts What makes a person rich ask

- Belagroprombank personal account Fransabank internet banking login

- How to make money on agricultural tourism in Russia How to open an agricultural estate in Belarus

- How much is the labor of a kindergarten teacher in our country and in other countries?