Sections of the site

Editor's Choice:

- Business with China - where to start, how to find suppliers + TOP-15 goods from China and a list of trading platforms

- Where to invest 1000 dollars

- Three common misconceptions and six life tips

- How can maternity capital be used - what needs can be spent on maternity capital

- Caramel apples - a new idea for business

- Ready business plan for beginners

- Gypsum tiles for stone: 7 advantages of the material

- How to buy the best and interesting unusual goods from China for home, gifts and sales on Aliexpress in Russian?

- Business plan for opening a bath

- Where to spend maternity capital before the child is 3 years old

Advertising

| Types and properties of plastics. Determining the type of plastic |

|

In modern cars, the proportion of plastic parts is constantly growing. The number of repairs on plastic surfaces is also growing; more and more often we are faced with the need to paint them. In many ways, the color of plastics differs from the color of metal surfaces, which is primarily due to the very properties of plastics: they are more elastic and have less adhesion to paintwork materials. And since the range of polymeric materials used in the automotive industry is very diverse, then if there weren't some universal repair materials capable of creating a high-quality decorative coating on many of their types, painters would probably have to receive a special education in chemistry. Fortunately, everything will actually turn out to be much simpler and we will not have to plunge headlong into the study of the molecular chemistry of polymers. But still, some information about the types of plastics and their properties, if only for the purpose of broadening one's horizons, will be clearly useful. Today you will find out Plastics - to the massesIn the 20th century, mankind went through a synthetic revolution, new materials - plastics - entered its life. Plastic can be safely considered one of the main discoveries of mankind; without its invention, many other discoveries would have been obtained much later, or they would not have been at all.

The first plastic was invented in 1855 by the British metallurgist and inventor Alexander Parks. When he decided to find a cheap substitute for the expensive ivory, from which billiard balls were made at the time, he could hardly imagine the significance of the product he received later. The ingredients of the future discovery were nitrocellulose, camphor and alcohol. A mixture of these components was heated to a fluid state, and then poured into a mold and solidified at normal temperature. This is how parkesin was born - the progenitor of modern plastics. From natural and chemically modified natural materials to fully synthetic molecules, the development of plastics came a little later - when a professor at the University of Freiburg German Hermann Staudinger discovered a macromolecule - the "brick" from which all synthetic (and natural) organic materials are built. This discovery earned the 72-year-old professor the Nobel Prize in 1953. Since then, everything has begun ... Almost every year from chemical laboratories there were reports of another synthetic material with new, unprecedented properties, and today millions of tons of all kinds of plastics are produced annually in the world, without which the life of a modern person is absolutely unthinkable. Plastics are used wherever possible: in providing comfortable life for people, agriculture, in all areas of industry. The automotive industry is no exception, where plastic is used more and more, irrepressibly displacing its main competitor, metal. Compared to metals, plastics are very young materials. Their history is less than 200 years old, while tin, lead and iron were familiar to mankind in ancient times - 3000-4000 years BC. NS. But despite this, polymeric materials are significantly superior in a number of indicators to their main technological competitor. The advantages of plasticsThe advantages of plastics over metals are obvious. First, plastic is much lighter. This allows to reduce the total weight of the vehicle and air resistance when driving, and thus - to reduce fuel consumption and, as a result, the emission of exhaust gases. The overall reduction in vehicle weight by 100 kg due to the use of plastic parts saves up to one liter of fuel per 100 km. Secondly, the use of plastics gives almost unlimited possibilities for shaping, allowing you to embody any design ideas into reality and get details of the most complex and ingenious shapes. The advantages of plastics also include their high corrosion resistance, resistance to weathering, acids, alkalis and other aggressive chemical products, excellent electrical and thermal insulation properties, high noise reduction coefficient ... In short, it is not surprising why polymer materials are so widely used in the automotive industry. Have there been any attempts to create an all-plastic car? But how! Just remember the notorious Trabant, produced in Germany over 40 years ago at the Zwick-Kau plant - its body was entirely made of laminated plastic. To obtain this plastic, 65 layers of very thin cotton fabric (supplied to the plant from textile factories), alternating with layers of ground cresol-formaldehyde resin, were pressed into a very strong material 4 mm thick at a pressure of 40 atm. and a temperature of 160 ° C for 10 minutes. Until now, the bodies of the GDR "Trabants", about which they sang songs, told legends (but more often they composed jokes), lie in many landfills in the country. They lie ... but they don't rust!

Trabant. The world's most popular plastic car Jokes as a joke, and there are still promising developments of all-plastic bodies of serial cars, many bodies of sports cars are entirely made of plastic. Traditionally, metal parts (hoods, fenders) on many cars are now also replaced with plastic ones, for example, in Citroën, Renault, Peugeot and others. But unlike the body panels of the popular "Trabi", the plastic parts of modern cars no longer cause an ironic smile. On the contrary, their resistance to shock loads, the ability of deformed areas to self-repair, the highest corrosion resistance and low specific gravity make this material deeply respected. Concluding the conversation about the advantages of plastics, one cannot fail to note the fact that, although with some reservations, still most of them lend themselves well to coloring. If the gray polymer mass did not have such an opportunity, it would hardly have gained such popularity. Why paint plastic?The need to color plastics is due, on the one hand, to aesthetic considerations, and on the other hand, to the need to protect the plastics. After all, nothing is eternal. Although plastics do not rot, but during operation and exposure to atmospheric influences, they still undergo aging and destruction processes. And the applied paint and varnish layer protects the plastic surface from various aggressive influences and, therefore, prolongs its service life. If in production conditions the painting of plastic surfaces is very simple - in this case we are talking about a large number of new identical parts made of the same plastic (and there are their own technologies), then a painter in an auto repair shop is faced with the problems of heterogeneity of materials of various parts. This is where you have to answer the question: “What is plastic in general? What is it made of, what are its properties and main types? " What is plastic?

In accordance with the domestic state standard:

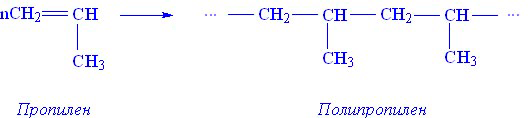

If from such a difficult description, even for reading, and not only for understanding, the description is removed the first word "plastics", perhaps, hardly anyone will guess what this is all about. Well, let's try to figure it out a bit. "Plastics" or "plastics" were so named because these materials are capable of softening when heated, becoming plastic, and then under pressure they can be given a certain shape, which is retained upon further cooling and hardening. The basis of any plastic is (the same "high molecular weight organic compound" from the definition above). The word polymer comes from the Greek words poly (many) and meros (parts or links). This is a substance whose molecules consist of a large number of identical, interconnected links. These links are called monomers("Mono" is one). This, for example, looks like a polypropylene monomer, the most commonly used type of plastic in the automotive industry:

The molecular chains of a polymer are made up of an almost infinite number of such pieces, connected into a single whole.

Polypropylene molecule chains By origin, all polymers are divided into synthetic and natural... Natural polymers form the basis of all animal and plant organisms. These include polysaccharides (cellulose, starch), proteins, nucleic acids, natural rubber and other substances. Although modified natural polymers find industrial applications, most plastics are synthetic. Synthetic polymers are prepared by chemical synthesis from the corresponding monomers. The feedstock is usually oil, natural gas or coal. As a result of a chemical reaction of polymerization (or polycondensation), many of the "small" monomers of the starting material are joined together, like beads on a string, into "huge" polymer molecules, which are then molded, cast, pressed or spun into a finished product. So, for example, polypropylene plastic is obtained from combustible propylene gas, from which bumpers are made:

Now you have probably guessed where the names of plastics come from. The prefix "poly-" ("many") is added to the name of the monomer: ethylene → polyethylene, propylene → polypropylene, vinyl chloride → polyvinyl chloride etc. International plastics abbreviations are abbreviations for their chemical names. For example, polyvinyl chloride is denoted as PVC(Polyvinyl chloride), polyethylene - PE(Polyethylene), polypropylene - PP(Polypropylene). In addition to the polymer (it is also called a binder), the composition of plastics can include various fillers, plasticizers, stabilizers, dyes and other substances that provide plastic with certain technological and consumer properties, for example, fluidity, plasticity, density, strength, durability, etc. Types of plasticsPlastics are classified according to various criteria: chemical composition, fat content, hardness. But the main criterion that explains the nature of the polymer is the nature of the behavior of the plastic when heated. On this basis, all plastics are divided into three main groups:

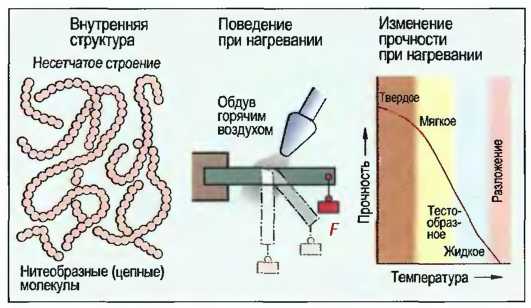

Belonging to a particular group is determined by the shape, size and location of macromolecules, along with the chemical composition. Thermoplastics (thermoplastic polymers, plastomers)Thermoplastics are plastics that melt when heated and return to their original state when cooled. These plastics are composed of linear or slightly branched molecular chains. At low temperatures, the molecules are located tightly next to each other and almost do not move, therefore, under these conditions, the plastic is hard and brittle. With a slight increase in temperature, the molecules begin to move, the bond between them weakens and the plastic becomes plastic. If you heat the plastic even more, the intermolecular bonds become even weaker and the molecules begin to slide relative to each other - the material passes into an elastic, viscous-flow state. With decreasing temperature and cooling, the whole process goes in reverse order.

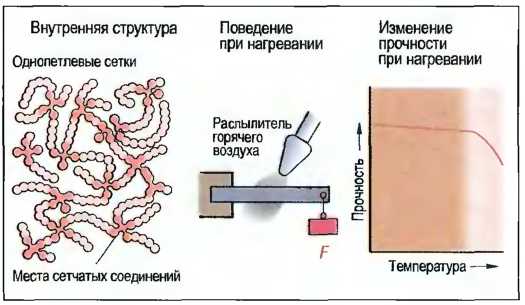

If overheating is avoided, in which the chains of molecules break down and the material decomposes, the heating and cooling process can be repeated as many times as you like. This feature of thermoplastics softening many times allows you to repeatedly process these plastics into certain products. That is, theoretically, one wing can be made from several thousand yogurt cups. From an environmental point of view, this is very important, since subsequent processing or disposal is a big problem for polymers. Once in the soil, plastic products decompose within 100-400 years! In addition, due to these properties, thermoplastics lend themselves well to welding and soldering. Cracks, fractures and deformations can be easily repaired by heat. Most of the polymers used in the automotive industry are thermoplastics. They are used for the production of various parts of the interior and exterior of the car: panels, frames, bumpers, radiator grilles, lamp housings and exterior mirrors, wheel covers, etc. Thermoplastics include polypropylene (PP), polyvinyl chloride (PVC), acrylonitrile-butadiene-styrene copolymers (ABS), polystyrene (PS), polyvinyl acetate (PVA), polyethylene (PE), polymethyl methacrylate (plexiglass) (PMMA), polyamide (PA) , polycarbonate (PC), polyoxymethylene (POM) and others. Reactoplastics (thermosetting plastics, duroplastics)If for thermoplastics the process of softening and hardening can be repeated many times, then the thermosetting plastics after a single heating (during the molding of the product) pass into an insoluble solid state, and do not soften with repeated heating. Irreversible curing occurs. In the initial state, thermosetting plastics have a linear structure of macromolecules, but when heated during the production of a molded article, the macromolecules are "crosslinked", creating a lattice spatial structure. It is due to this structure of closely linked, "cross-linked" molecules that the material is hard and inelastic, and loses the ability to re-enter a viscous-flow state.

Because of this feature, thermosetting plastics cannot be recycled. Also, they cannot be welded and molded in a heated state - when overheated, the molecular chains disintegrate and the material collapses. These materials are sufficiently heat-resistant, so they are used, for example, for the production of crankcase parts in the engine compartment. Large-size external body parts (hoods, fenders, trunk lids) are produced from reinforced (for example, fiberglass) thermosets. The group of thermosets includes materials based on phenol-formaldehyde (PF), urea-formaldehyde (UF), epoxy (EP) and polyester resins. Elastomers are plastics with highly elastic properties. When exposed to force, they show flexibility, and after relieving stress, they return to their original shape. Elastomers differ from other elastic plastics in their ability to maintain their elasticity over a wide temperature range. So, for example, silicone rubber remains elastic in the temperature range from -60 to +250 ° C. Elastomers, like thermosets, consist of spatially reticulated macromolecules. Only unlike thermosets, elastomer macromolecules are located more widely. It is this placement that determines their elastic properties.

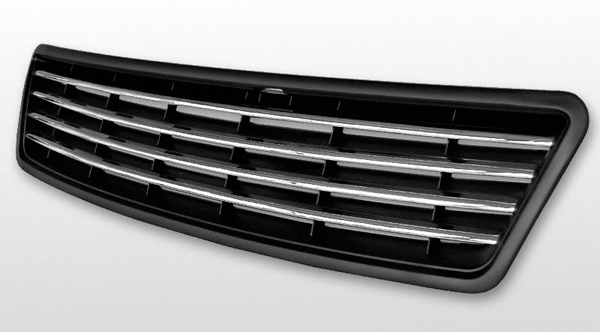

Due to their reticular structure, elastomers are infusible and insoluble, like thermosets, but they swell (thermosets do not swell). The elastomer group includes various rubbers, polyurethane and silicones. In the automotive industry, they are used mainly for the manufacture of tires, seals, spoilers, etc. All three types of plastics are used in the automotive industry. Also available are blends of all three types of polymers - the so-called "blends" (blends), the properties of which depend on the ratio of the mixture and the type of components. Determination of the type of plastic. MarkingAny repair to a plastic part must begin by identifying the type of plastic from which the part is made. If in the past this was not always easy, now it is easy to "identify" plastic - all parts are usually marked. Manufacturers usually stamp the designation of the type of plastic on the inside of the part, be it a bumper or a mobile phone cover. The type of plastic is usually enclosed in characteristic brackets and may look like this:> PP / EPDM<, >PUR<,

Control task: remove the cover of your mobile phone and see what type of plastic it is made of. Most often it is> PC<. There can be many options for such abbreviations. We will not be able to consider everything (and there is no need for that), so we will focus on several types of plastics most common in the automotive industry. Examples of the most common types of plastic used in the automotive industryPolypropylene - PP, modified polypropylene - PP / EPDM

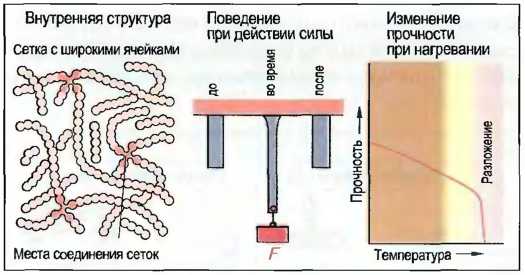

The most common type of plastic in the automotive industry. In most cases, when repairing damaged or painting new parts, we will have to deal precisely with various modifications of polypropylene. Polypropylene has, perhaps, a combination of all the advantages that plastics can have: low density (0.90 g / cm³ - the lowest value for all plastics), high mechanical strength, chemical resistance (resistant to diluted acids and most alkalis, detergents, oils, solvents), heat resistance (begins to soften at 140 ° C, melting point 175 ° C). It hardly undergoes stress corrosion cracking and has good recovery properties. In addition, polypropylene is an environmentally friendly material. The characteristics of polypropylene make it an ideal material for the automotive industry. For his such valuable properties, he even received the title of "King of Plastics". Almost all bumpers are made on the basis of polypropylene, and this material is also used in the manufacture of spoilers, interior parts, dashboards, expansion tanks, radiator grilles, air ducts, housings and battery covers, etc. In everyday life, even suitcases are made of polypropylene. When casting most of the above parts, not pure polypropylene is used, but its various modifications. "Pure" unmodified polypropylene is very sensitive to ultraviolet radiation and oxygen, it quickly loses its properties and becomes brittle during use. For the same reason, paint and varnish coatings applied to it cannot have durable adhesion. The additives introduced into polypropylene - more often in the form of rubber and talc - significantly improve its properties and make it possible to paint it. Only modified polypropylene can be dyed. On "pure" polypropylene, the adhesion will be very weak! Pure polypropylene> PP< изготавливают бачки омывателей, расширительные емкости, одноразовую посуду, стаканчики и т.д. Any modifications of polypropylene, no matter how long the abbreviation of its marking, is indicated by the first two letters anyway, as> PP ...<. Наиболее распространенный продукт этих модификаций — >PP / EPDM< (сополимер полипропилена и этиленпропиленового каучука). ABS (copolymer of acrylonitrile, butadiene and styrene)

ABS is elastic, but at the same time impact-resistant plastic. The component of rubber (butadiene) is responsible for elasticity, acrylonitrile is responsible for strength. This plastic is sensitive to ultraviolet radiation - under its influence the plastic ages quickly. Therefore, ABS products cannot be kept in the light for a long time and must be painted. It is most commonly used in the production of lamp housings and exterior mirrors, radiator grilles, dashboard liners, door trims, wheel caps, rear spoilers, etc. Polycarbonate - PC

One of the most impact-resistant thermoplastics. To understand how durable polycarbonate is, the fact that this material is used in the manufacture of bulletproof bank racks is enough. In addition to strength, polycarbonates are characterized by lightness, resistance to light aging and temperature extremes, and fire safety (this is a difficult-to-ignite, self-extinguishing material). Unfortunately, polycarbonates are quite sensitive to solvents and tend to crack under the influence of internal stress. Unsuitable aggressive solvents can seriously impair the strength characteristics of plastic, therefore, when painting parts where strength is of paramount importance (for example, a motorcycle helmet made of polycarbonate), you need to be especially careful and strictly follow the manufacturer's recommendations, and sometimes even fundamentally refuse to paint. But spoilers, radiator grilles and polycarbonate bumper panels can be painted without problems. Polyamides - PA

Polyamides are tough, durable and elastic materials. Parts made of polyamide can withstand loads close to the loads permissible for non-ferrous metals and alloys. Polyamide has high wear and chemical resistance. It is almost immune to most organic solvents. Most often, polyamides are used for the production of removable car caps, various bushings and liners, pipe clamps, door lock tongues and latches. Polyurethane - PU, PUR

Before the widespread introduction of polypropylene in the production, polyurethane was the most popular material for the manufacture of various elastic car parts: steering wheels, mud covers, pedal covers, soft door handles, spoilers, etc. Many people associate this type of plastic with the Mercedes brand. Bumpers, side door strips, sills on almost all models were made of polyurethane until recently. The production of parts from this type of plastic requires less sophisticated equipment than for polypropylene. Currently, many private companies, both abroad and in the countries of the former Soviet Union, prefer to work with this type of plastic for the manufacture of all kinds of parts for car tuning. Fiberglass - SMC, BMC, UP-GF

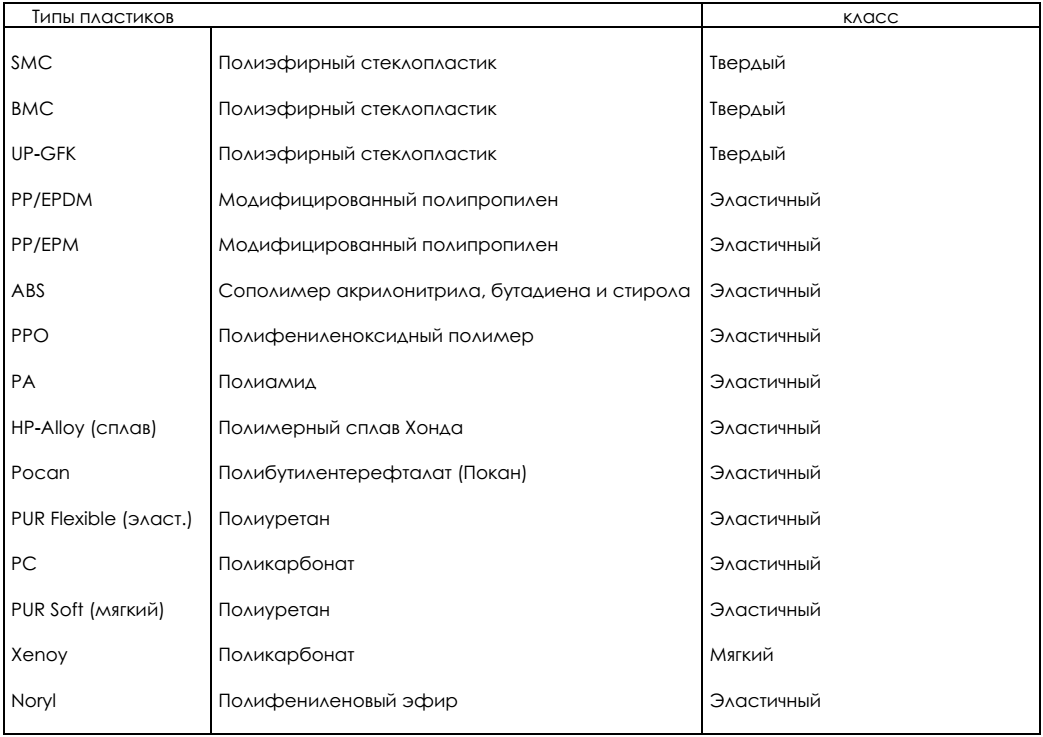

Fiberglass plastics are one of the most important representatives of the so-called "reinforced plastics". They are made on the basis of epoxy or polyester resins (these are thermosets) with fiberglass as a filler. High physical and mechanical properties, as well as resistance to the effects of various aggressive media have determined the widespread use of these materials in many areas of industry. A well-known product used in the production of American minivan bodies. In the manufacture of fiberglass products, it is possible to use the "sandwich" technology, when the parts consist of several layers of different materials, each of which meets certain requirements (strength, chemical resistance, abrasion resistance). The legend of an unknown plasticHere we are holding in our hands a plastic part that does not have any identification marks on it, no markings. But we desperately need to find out its chemical composition, or at least the type - it is thermoplastic or thermosetting plastic. Because, if we are talking, for example, about welding, then it is possible only with thermoplastics (adhesive compositions are used to repair thermosetting plastics). In addition, only materials of the same name can be welded, dissimilar materials simply do not interact. In this regard, it becomes necessary to identify the plastic "no name" in order to correctly select the same welding filler. Identifying the type of plastic is not an easy task. Analysis of plastics is carried out in laboratories according to various indicators: according to the spectrogram of combustion, reaction to various reagents, smell, melting point, and so on. Nevertheless, there are several simple tests that allow you to determine the approximate chemical composition of plastic and assign it to one or another group of polymers. One of these is the analysis of the behavior of a plastic sample in an open fire source. For the test, we need a ventilated room and a lighter (or matches), with which we need to carefully set fire to a piece of the test material. If the material melts, then we are dealing with a thermoplastic, if it does not melt, we have a thermosetting plastic in front of us. Now we remove the flame. If the plastic continues to burn, it could be ABS, polyethylene, polypropylene, polystyrene, plexiglass, or polyurethane. If it goes out - most likely it is polyvinyl chloride, polycarbonate or polyamide. Next, we analyze the color of the flame and the smell formed during combustion. For example, polypropylene burns with a bright bluish flame, and its smoke has a pungent and sweet smell, similar to the smell of sealing wax or burnt rubber. Polyethylene burns with a weak bluish flame, and when the flame goes out, the smell of a burning candle is felt. Polystyrene burns brightly, and at the same time smokes a lot, and smells quite nice - it has a sweetish floral scent. Polyvinyl chloride, on the other hand, smells unpleasant - chlorine or hydrochloric acid, and polyamide - burnt wool. Something about the type of plastic can be said by its appearance. For example, if there are obvious traces of welding on a part, then it is probably made of thermoplastic, and if there are traces of burrs removed with emery, then it is thermosetting plastic. You can also do a hardness test by trying to cut a small piece of plastic with a knife or razor blade. The chips will be removed from the thermoplastic (it is softer), but the thermosetting plastic will crumble. Or another way: immersing the plastic in water. This method makes it quite easy to identify plastics that are part of the polyolefin group (polyethylene, polypropylene, etc.). These plastics will float on the surface of the water, as their density is almost always less than unity. Other polymers have a density greater than unity, so they will sink. These and other signs by which you can determine the type of plastic are presented below in the form of a table. P.S. In we will pay attention to the preparation and painting of plastic parts. BonusesFull size versions of images will open in a new window when you click on the image! Deciphering the designation of plastics

Legend for the most common plastics

Classification of plastics depending on hardness

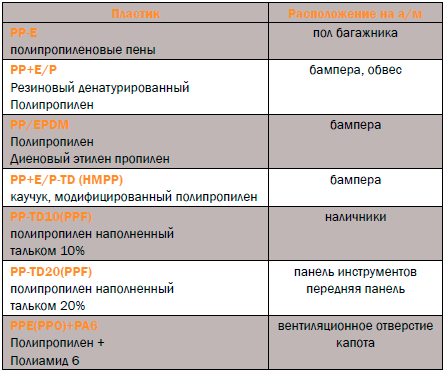

The main modifications of polypropylene and their areas of application in the car

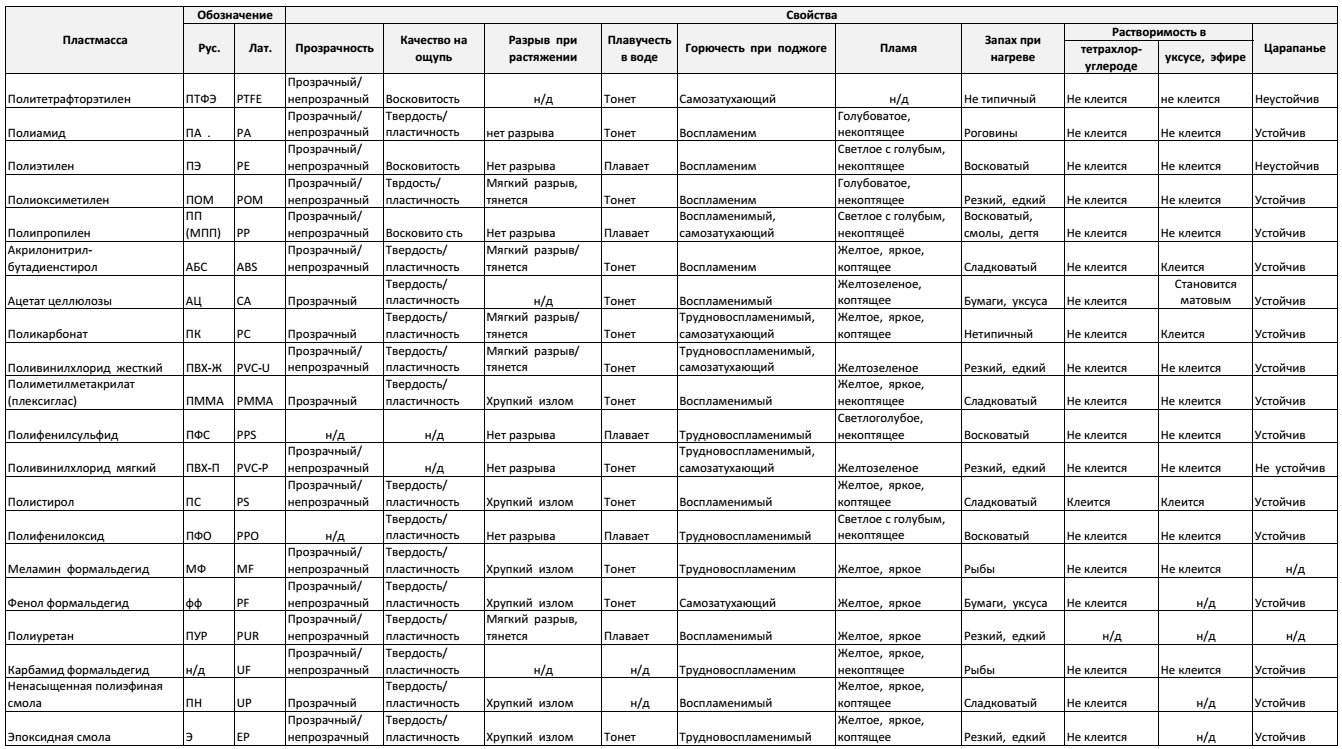

Methods for determining the type of plastic

|

| Read: |

|---|

Popular:

New

- Examples of drawing up (writing) a resume

- Early withdrawal of a disciplinary sanction: the order of application, as happens after the expiration of time, a sample of the petition and order to cancel the punishment

- Fixed-term employment contract: sample

- An example of internal labor regulations in an organization

- Order of the Ministry of Internal Affairs of the Russian Federation dated 31.01. Legislative base of the Russian Federation. Order of the ministry of internal affairs of the russian federation

- Business with China - where to start, how to find suppliers + TOP-15 goods from China and a list of trading platforms

- Where to invest 1000 dollars

- Three common misconceptions and six life tips

- How can maternity capital be used - what needs can be spent on maternity capital

- Caramel apples - a new idea for business